|

Size Range: |

DN50~600mm NPS 2”-24” (Larger size on request) |

| Max Working Press.: |

DN50~DN250: 10Bar NPS2~NPS10:150Psi DN300~DN450: 7Bar NPS12~NPS18:90Psi DN500~DN600: 4Bar NPS20~NPS24:60Psi |

| Temp. Range: | -29...+200℃ |

|

Seal Tightness: |

According to MSS SP-81 |

|

Body Material: |

Carbon Steel, Stainless Steel, Special Allory |

|

Gate Material: |

Stainless Steel Chrome Plated, Special Allory |

|

Seat Material: |

EPDM (120°C) /Viton(200°C)/NBR(90°C) |

| Face to Face: | MSS SP-81 |

|

Flange Standard: |

GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN1092-1 |

|

Applications: |

Mining/Pulp&Paper/Power Plant/Steel&Metal/Cement |

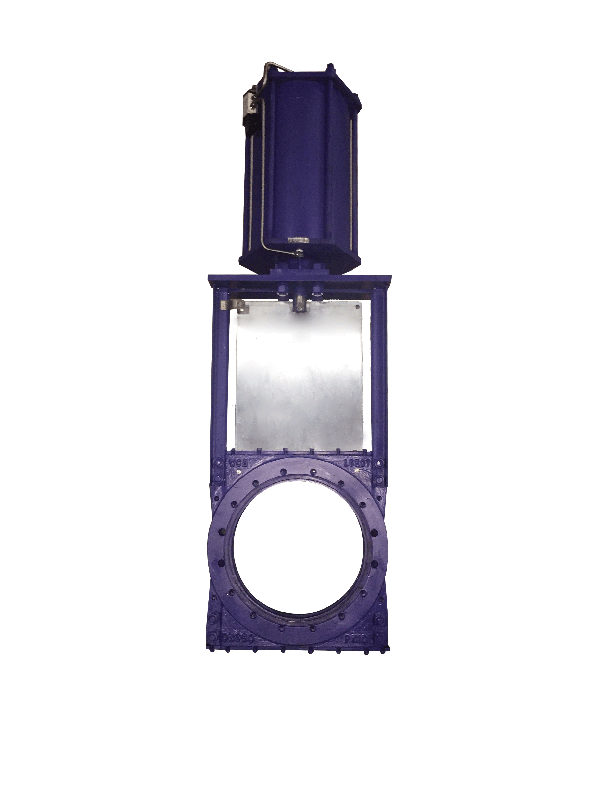

Introduction:

The HKPZ-series slurry knife gate valve is a bi-directional wafer knife gate valve equipped with two metal

reinforced rubber sleeves, designed for applications with abrasive slurries.

Features:

1. Body:

a) Full port design minimizes pressure drop and maximizes flow capacity.

b) Port at body bottom allows media to be discharged, avoid media accumulation at lower body.

2. Gate:

a) Rectangular gate is machined to a sharp edge for big shear stress without damaging seats.

b) Gate surface is well polished at both sides for tight seal and less jamming.

c) Gate is hard chrome coated for metal sealing valve.

3. Seat:

a) Two seats, metal reinforced rubber sleeves can handle flow in both directions.

b) The rubber sleeves are replaceable with easy installation.

c) When gate is at open position, the seats compress each other tightly to achieve bubble tight

seal and protect valve inner cavity from flushing. Consequently, gate can be changed without

shutting down pipeline.

4. Other:

a) Double thrust bearing minimize the operating torque.

| No. | File Name | Download Link |

| 1 | Slurry Knife Gate Valve | Download |