The function of a knife gate valve includes the following:

-

Fluid Shut-off: The primary function of a knife gate valve is to shut off or cut off the flow of fluid. When the valve is closed, the gate or blade embeds into the seat, effectively preventing the passage of fluid and achieving fluid shut-off.

-

-

Fluid Control: While the main purpose of a knife gate valve is to shut off fluid flow, in some applications, partial control of the fluid can be achieved by adjusting the valve's opening.

-

-

Quick Closure: Knife gate valves are often designed for quick closure, allowing rapid shut-off in emergency situations to prevent accidents.

-

-

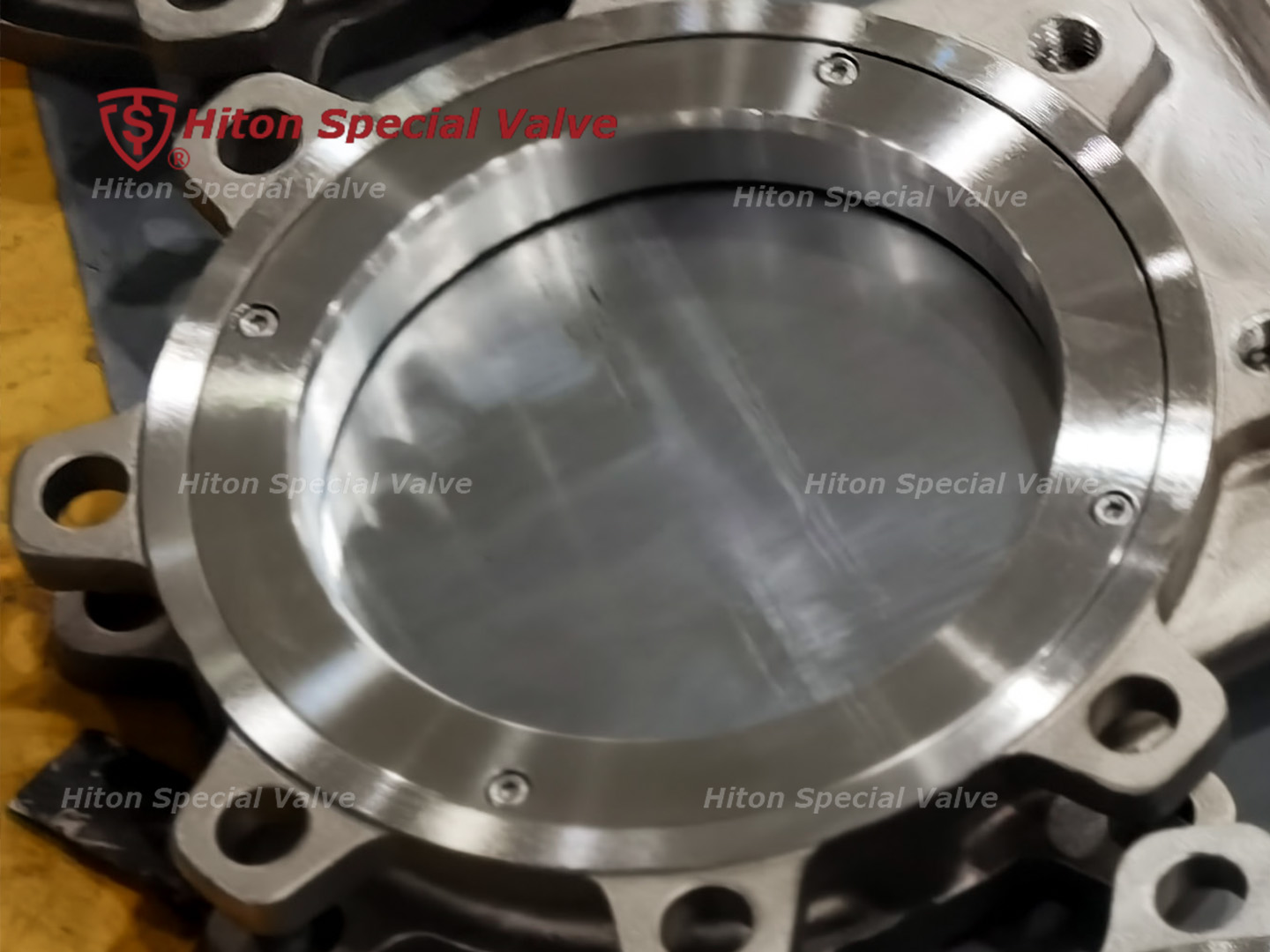

Sealing Performance: Knife gate valves provide good sealing performance when closed, reducing the risk of fluid leakage. This is particularly crucial in processes where stringent leakage requirements exist.

-

-

Suitable for High Flow Velocity: Due to their special structure, knife gate valves are typically suitable for applications with high-speed fluid flow, as the gate is less susceptible to fluid impact when closed.

-

-

Application in Water and Wastewater Treatment: Knife gate valves are commonly used in water treatment and wastewater systems to control and shut off the flow of clear water, wastewater, and other liquid mediums.

-

-

Suitable for High-Pressure Systems: The structural characteristics of knife gate valves make them adaptable to high-pressure systems, effectively preventing fluid leakage.

In summary, knife gate valves play a vital role in industrial applications, particularly in processes that require emergency fluid shut-off, demand excellent sealing performance, and operate under high-pressure or high-velocity fluid conditions.