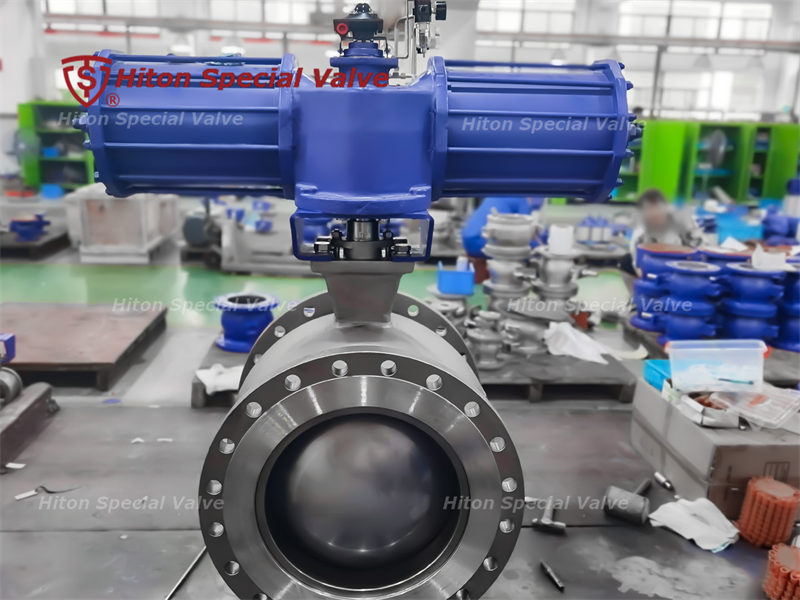

The electric operation of a V-ball valve is typically achieved using an electric actuator. Here is an explanation of the electric operation of V-ball valves:

Electric Actuator: An electric actuator is a device used to control the valve's opening and closing. It typically consists of an electric motor, a gear mechanism, a control circuit, and a positioner. The electric motor of the actuator provides power, and the gear mechanism transmits the rotational force of the motor to the valve's ball-shaped core.

Control System: Electric actuators are controlled through connection to a control system. This can involve operators in a control room using a control panel or an automation system. It can also include remote control and monitoring.

Switching Operation: The electric motor of the actuator can move the valve core from fully closed to fully open or to an intermediate position based on control signals. This allows for precise flow control and fluid cutoff.

Position Feedback: Many electric actuators come equipped with position feedback devices to provide information about the valve core's position to the control system. This helps in monitoring the valve's status and performance.

Emergency Shutdown: In emergency situations, electric actuators can typically cut off power immediately, rapidly closing the valve to stop fluid flow. This is a safety feature of electrically operated valves.

Automation: Electric operation allows V-ball valves to be integrated with automation systems for automatic flow regulation according to process requirements. This is highly useful in industrial process control.

The primary advantages of electric operation include remote control, high precision, rapid response, and automation capabilities. This makes V-ball valves particularly useful in applications requiring accurate control of fluid flow, such as in the chemical, pharmaceutical, and water treatment industries. Electric operation is typically employed in cases where frequent or precise flow control is necessary.