Here are the main features and working principles of a pneumatic V-port ball valve (segment ball valve):

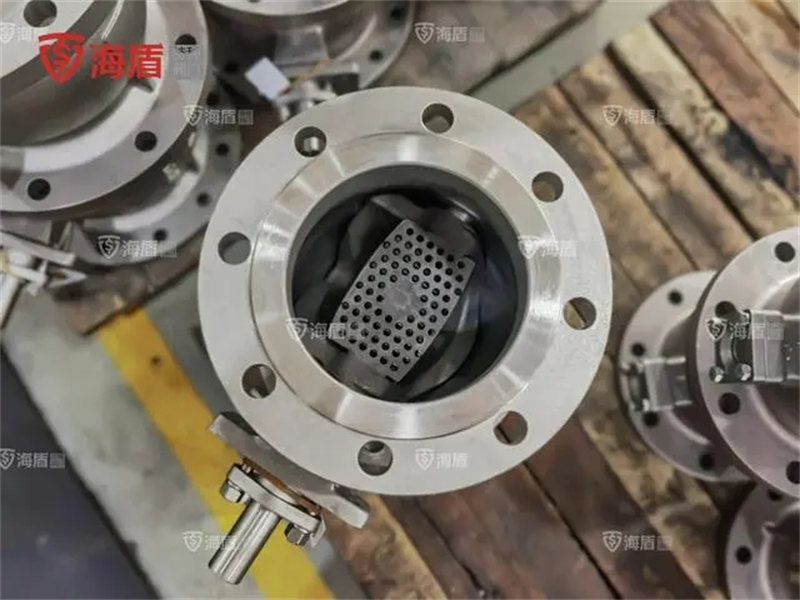

1. V-port ball valve (segment ball valve) Design: Pneumatic V-port ball valve (segment ball valve) typically adopt the design of a V-port ball valve (segment ball valve), with a valve core featuring a V-shaped aperture that controls fluid flow by rotation. This design is suitable for high-precision flow regulation and the ability to cut through the medium.

2. Pneumatic Actuator: Pneumatic V-port ball valve (segment ball valve) are equipped with a pneumatic actuator, which is a device operated by compressed air or gas. The pneumatic actuator can rotate the valve's core to open or close, thereby controlling fluid flow. This allows for automation of operations and remote or automatic control as needed.

4. Fast Response Time: Due to the use of a pneumatic actuator, pneumatic V-port ball valve (segment ball valve) typically have a fast response time. They can quickly adjust the position of the valve core to meet changing process requirements.

5. Wide Range of Applications: Pneumatic V-port ball valve (segment ball valve) are suitable for various applications that require automated or remote flow control, especially in cases where high-precision control is needed, remote operation is required, or in hazardous environments.