V-port valves are a type of valve with special design features, which primarily include the following points:

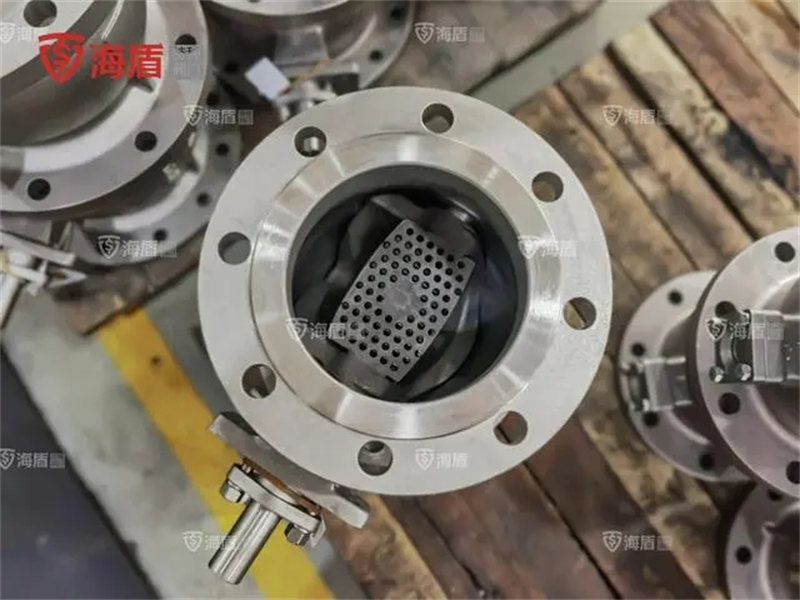

Streamlined Flow Path: V-port valves feature a V-shaped design in their flow path, allowing for smooth fluid flow, reduced resistance, and lower energy consumption.

Precise Flow Control: V-port valves enable precise flow control through the rotation of the valve body, making them suitable for processes that require accurate flow regulation.

Zero Leakage: V-port valves utilize a metal-to-metal sealing design, ensuring zero leakage and preventing damage to the environment and equipment due to media leaks.

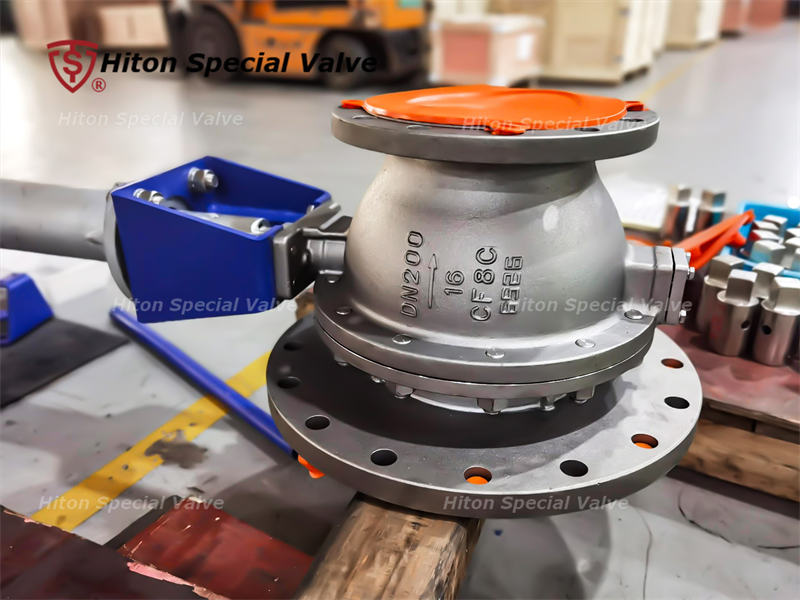

High-Temperature and High-Pressure Resistance: V-port valves typically use materials capable of withstanding high temperatures and high pressures, such as high-temperature alloy steel or stainless steel, enabling them to operate reliably in high-temperature and high-pressure conditions and suitable for high-temperature and high-pressure pipeline systems.

Quick Shut-Off: V-port valves have the ability to rapidly shut off the flow of media, contributing to improved system safety and operational efficiency.

Wear Resistance: The ball and seat ring of V-port valves are typically made from wear-resistant materials, providing an extended service life even under high-speed fluid flow conditions.

Wide Applications: V-port valves find extensive use in fluid control systems across various industries, including petroleum, chemical, power generation, metallurgy, pharmaceuticals, papermaking, food, and more. They are especially well-suited for processes that demand precise flow control.

Translation into English:

V-port valves are a type of specially designed valve with several distinctive characteristics, including:

Streamlined Flow Path: V-port valves feature a V-shaped design in their flow path, which enables smooth fluid flow, reduces resistance, and lowers energy consumption.

Precise Flow Control: V-port valves allow for precise flow control by rotating the valve body, making them suitable for processes that require accurate flow regulation.

Zero Leakage: V-port valves use a metal-to-metal sealing design that ensures zero leakage, preventing damage to the environment and equipment from media leaks.

High-Temperature and High-Pressure Resistance: V-port valves typically employ materials capable of withstanding high temperatures and pressures, such as high-temperature alloy steel or stainless steel. This allows them to operate reliably in high-temperature and high-pressure conditions and makes them suitable for high-temperature and high-pressure pipeline systems.

Quick Shut-Off: V-port valves can rapidly shut off the flow of media, improving system safety and operational efficiency.

Wear Resistance: The ball and seat ring of V-port valves are usually made from wear-resistant materials, providing an extended service life even under conditions of high-speed fluid flow.

Wide Range of Applications: V-port valves are widely used in fluid control systems across various industries, including petroleum, chemical, power generation, metallurgy, pharmaceuticals, papermaking, food, and more. They are particularly well-suited for processes that require precise flow control.